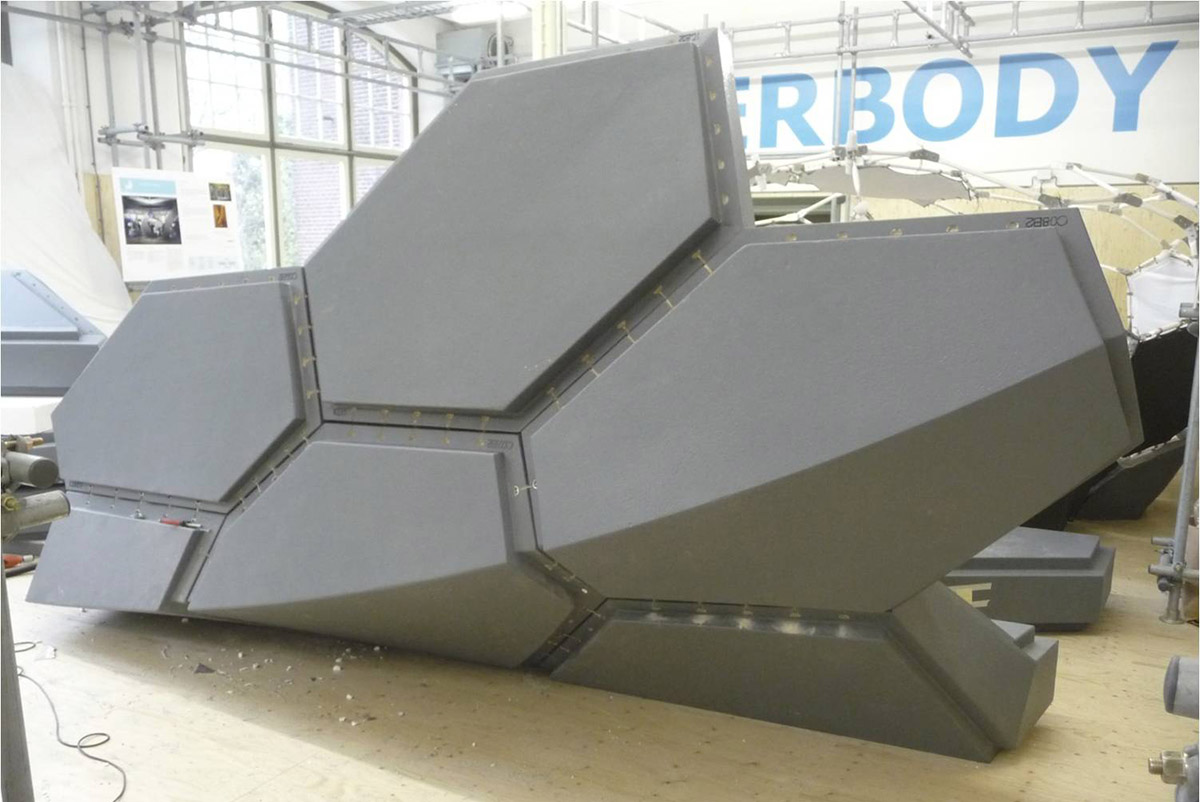

004 protoCELL

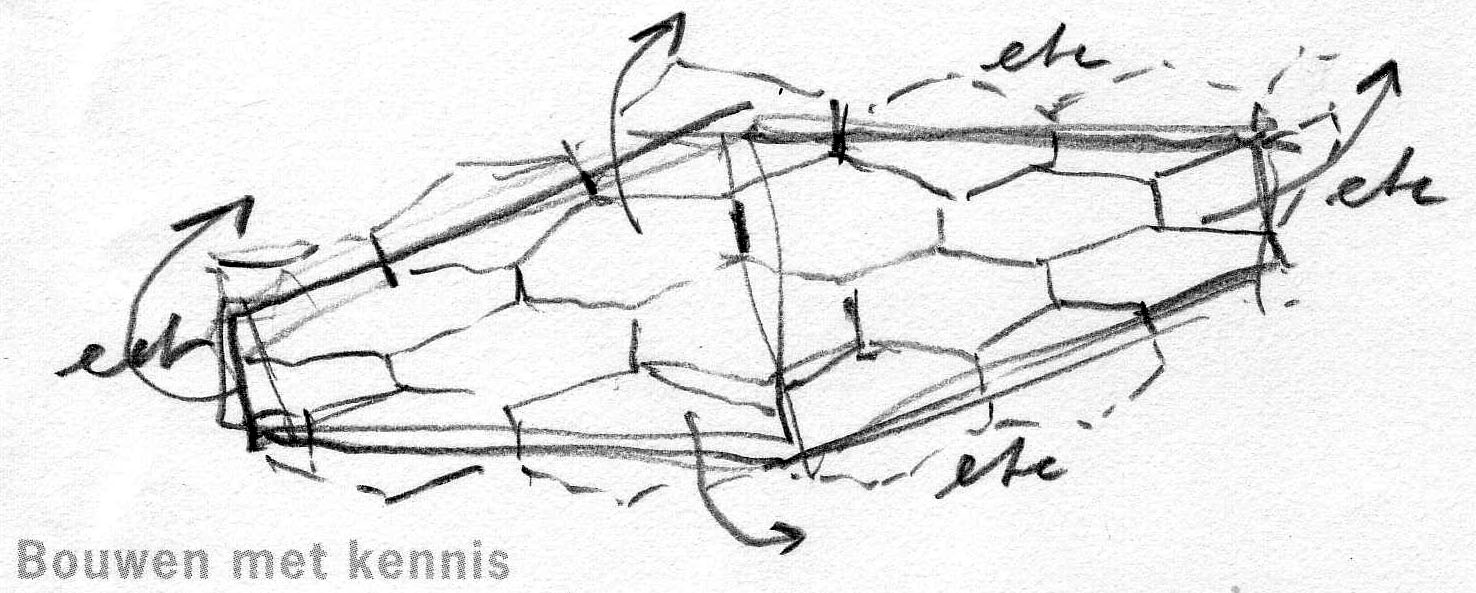

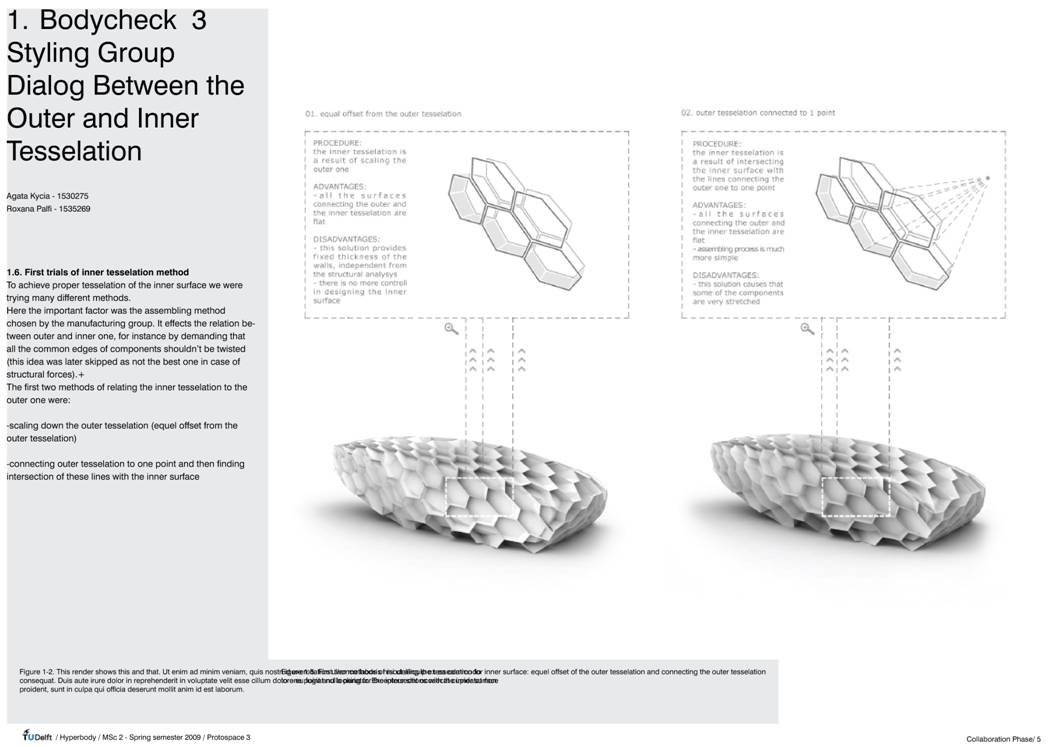

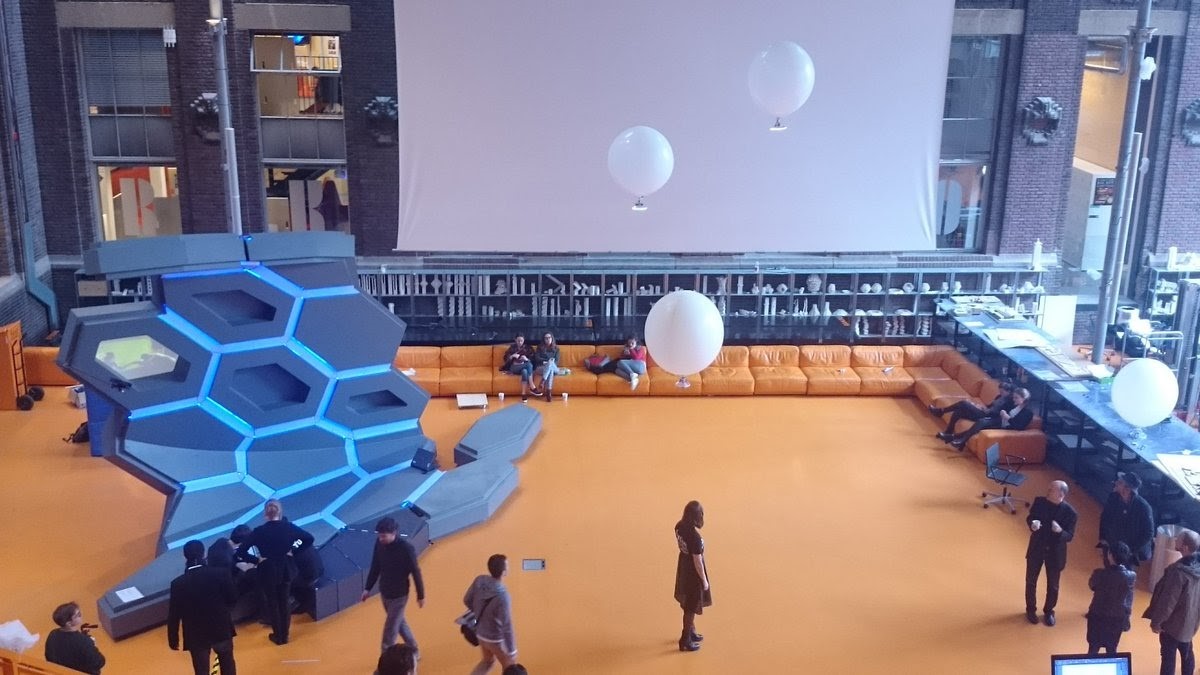

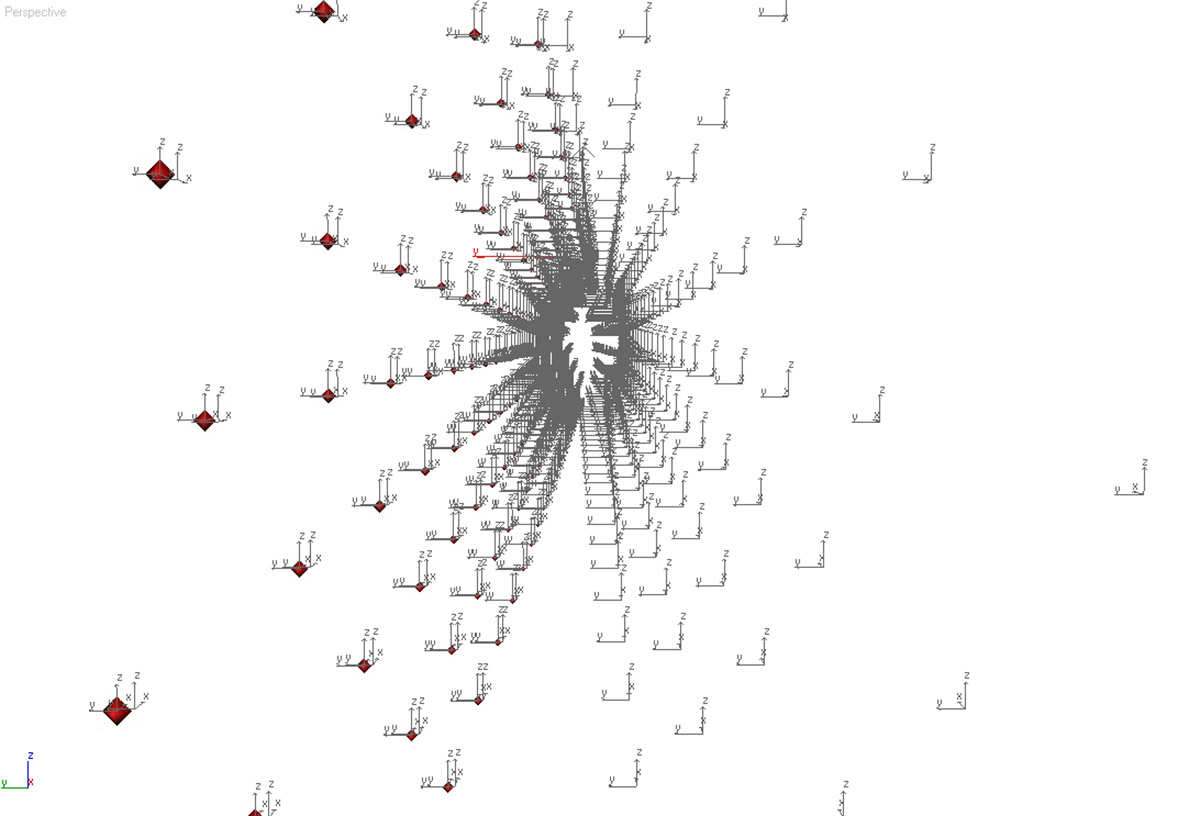

The protoSPACE lab 2.0 in the iWEB had to close down due to the 2008 fire, which destroyed the Faculty of Architecture. In Spring 2010 we opened protoSPACE 3.0 inside the walls of a new BK City. In the 2009 MSc2 course Hyperbody students and ONL architects designed a new protoSPACE 4.0 lab, a standalone pavilion between BK City and the Delft Science Centre. For protoSPACE 4.0 we developed a complete new building system based on an assemblage of large unique CNC produced building blocks. The prototypical building block we named protoCELL. The parametric protoCELL unit comes in a series of interacting function-specific swarms: daylight swarm, artificial light swarm, ventilation swarm, interaction swarm, heating swarm, display swarm. Each featured swarm consists of 10-20 parametric building components. The different swarms interact in a loose configuration, intermingling the specified functional units, but never betraying to which swarm one belongs. the units are CNC milled from polystyrene foam and coated with a strong polyurea skin. All building blocks of all swarms are structural as well as provide for insulation. The hundred large building blocks of the proposed protoSPACE 4.0 fit together like the unique pieces of a 3d puzzle. The gravity center of the units form the point cloud of reference points. The reference points are further specified as to form the details of the geometric relations between the units. Each reference points thus becomes a group of parametric related points.